The amount of sub-standard security cable in the UK has been a problem for some time, so the BSI has introduced a new standard which will come into force on 1st April 2016. The new standard will give installers clear indication of the quality of the cable they are using and in turn reduce the number of installations failing as a result of poor quality materials.

The amount of sub-standard security cable in the UK has been a problem for some time, so the BSI has introduced a new standard which will come into force on 1st April 2016. The new standard will give installers clear indication of the quality of the cable they are using and in turn reduce the number of installations failing as a result of poor quality materials.

According to Nigel van Woerdekom of CQR Fire & Security: “Since the introduction of PD6662 which did not included a requirement for cables to meet a dedicated standard for used in alarm systems; there has been an increase in the amount of poorly manufactured cables available on the UK market. These cables have caused alarm systems to experience faults and in some cases failures and are often the weakest link and always the most difficult to replace in an otherwise high quality installation. Reputable installers have fallen foul of these poor quality cables because there was no standard which had minimum requirements for their design, manufacture and identification.”

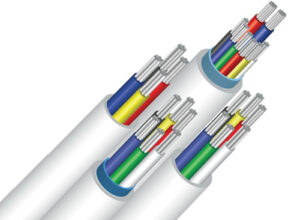

The security industry has recognised this weakness and with the BSI have published BS4737-3.30:2015, ‘Specification for insulated and sheathed cables for interconnection wiring’. The new standard gives requirements for the construction and performance of insulated and sheathed cables for interconnecting wiring used in alarm systems. The standard is applicable to cables intended for use with voltages up to 50 V, either AC or DC. However the standard excludes cables for fire alarm systems.

Classifications

“The new standard is no longer specific to PVC cable,” confirms Tony Weeks of NSI. “It provides three classifications of cable construction, a more robust schedule of tests, and guidance on the application of cables. The need for a new standard was prompted for a number of reasons including the need for an up-to-date standard with wider application and a perception of a certain amount of poor quality and/or fake cable on the market.”

The three types of cable identified by the standard are:

- Type 1:- The sheathing and insulation material shall be Low Smoke Halogen Free with a maximum conductor resistance of 100 ohms/km.

- Type 2:- The sheathing and insulation material shall be PVC with a maximum conductor resistance of 100 ohms/km

- Type 3:- The sheathing and insulation material shall be PVC with a maximum conductor resistance of 155 ohms/km

It includes minimum requirements for the application and thickness of the sheathing and insulation materials, construction of the conductor, and electrical tests of the cable. A number of routine and sample tests have also been included to ensure that the cables produced meet with these requirements.

Read the full article in the December edition of PSI magazine