Michael Akinla of Panduit looks at the findings of recently published white paper

Twisted pair copper structured cabling a reliable and affordable media to deploy Ethernet networks and external connected security and safety systems are essential in the operation of all large buildings and campus sites. The larger the site the more expensive the infrastructure to support those systems. A key element in the alignment of cable standardisation and application is the limitation of 100-metres is the maximum cabling channel length.

Demand for extended-reach Ethernet cabling, surpassing the traditional 100m channel limit of twisted pair copper, is increasing and driven by the need to extend Ethernet networks and connect devices like security cameras, wireless access points, and access control systems situated.

Panduit’s recently published white paper looks at 150m PoE copper with 1 gigabit capacity and found it offers a cost-effective alternative to installing additional intermediate distribution frames, consolidation points or transitioning to fibre. Extending copper reach simplifies infrastructure, reduces costs while maintaining reliability and simplicity. However, there are considerations:

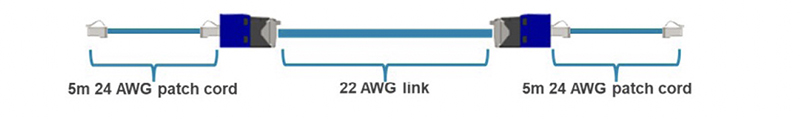

- Cable Selection: Use higher-category cables, like Category 6 or 6A, with larger conductors (e.g. 22 AWG). These cables exhibit lower insertion loss and enhanced signal integrity over extended distances.

- Performance Standards: Choose cabling that meets or exceeds industry standards for parameters like insertion loss, near-end crosstalk (NEXT), and return loss, which are critical for data transmission quality over longer runs.

- Power over Ethernet (PoE) Compatibility: Ensure cabling supports the required PoE standards, especially for devices needing power delivery over the same cable and should accommodate the power levels necessary for devices like IP cameras and access points.

Furthermore,consider installation best practice and deploy appropriately for the installation environments. Ensure the cabling and connectors can withstand conditions such as temperature variations, moisture, and electromagnetic interference. Moreover,proper grounding and bonding are essential to protect the network from electrical surges and to minimise noise interference, thereby ensuring reliable performance.

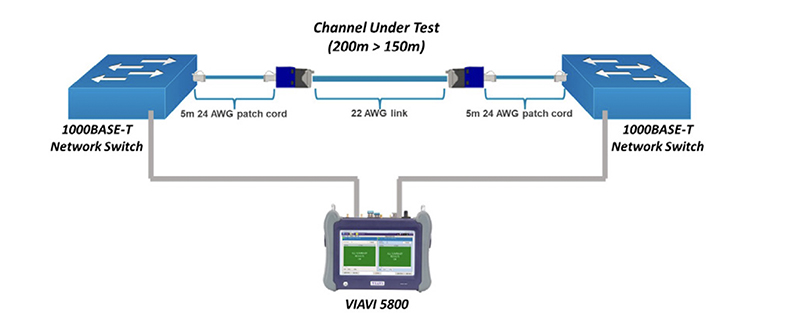

Conduct thorough testing of the extended cabling channels to confirm they meet performance specifications. This includes assessing parameters like insertion loss, propagation delay, and resistance unbalance. Use industry-standard testing devices to ensure accurate measurements and reliable validation of the cabling infrastructure.

While extending cabling beyond 100m is feasible, surpassing the tested 150m channel length, can lead to signal degradation and unreliable network performance. Our testing found that 140m PL of 22AWG Cat 6 or Cat 6A, coupled with 10m 24AWG Cat 6 or 6A patch cords provided consistent performance.

By carefully selecting appropriate cabling, adhering to installation best practices, and conducting rigorous testing, organisations can effectively implement extended-reach copper cabling solutions that meet current and future demands.

Read the Extending Copper Reach white paper here